Understanding the Role of an I/O Controller in Industrial Automation

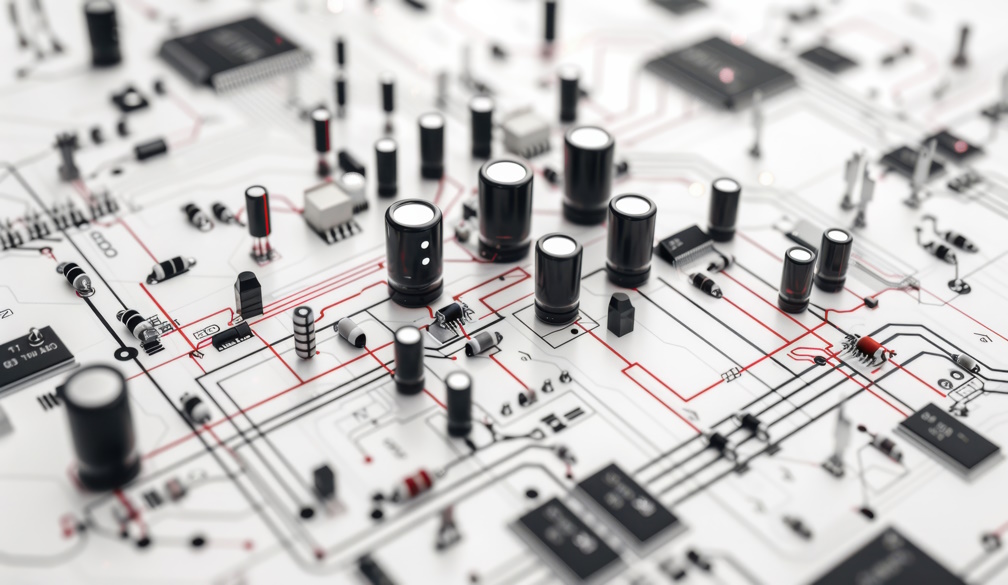

In today’s highly automated environments, efficient communication between hardware and software is essential. One of the key components enabling this communication is the I/O controller. Short for Input/Output controller, it acts as the crucial bridge between the processor and peripheral devices such as sensors, actuators, switches, and more. Without a properly functioning I/O controller, modern systems — from industrial machinery to smart automation — would simply not operate at optimal levels.

What Is an I/O Controller?

An I/O controller is a hardware device or embedded system that manages data communication between a central processor and external components. It handles the reading of input signals and controls output devices based on the commands received from the central system. This makes it a key part of programmable logic controllers (PLCs), distributed control systems (DCS), and other industrial automation setups.

The controller ensures that data is collected from the environment (such as temperature sensors or proximity switches) and that outputs (such as relays or actuators) are executed based on system logic. This process must be reliable, fast, and precise, especially in time-sensitive industrial operations.

How an I/O Controller Works

The I/O controller functions by connecting to multiple input and output devices. Inputs could include devices like sensors, cameras, or switches, while outputs might be motors, solenoids, or lights. The controller processes incoming data from input devices and translates this into specific actions or signals to be sent to output devices.

In many setups, I/O controllers are installed within control cabinets or panels, often modular in nature to allow easy scalability. Communication between the controller and the main CPU often happens via industrial communication protocols such as Modbus, Ethernet/IP, or Profibus.

Types of I/O Controllers

There are various kinds of I/O controllers, generally classified into digital and analog types. Digital I/O controllers deal with binary data — on/off or high/low signals — while analog controllers handle variable input and output values like voltage, current, or resistance.

Some I/O controllers are designed for simple point-to-point control, while others support complex networked environments with multiple channels and devices. In recent years, advancements have led to the development of intelligent I/O controllers that include built-in diagnostics, status indicators, and even remote access features.

Benefits of Using an I/O Controller

One of the biggest advantages of integrating an I/O controller into your automation system is increased reliability. Since these devices are purpose-built to manage inputs and outputs accurately, they help minimise signal loss, noise interference, and processing delays.

Another significant benefit is modularity. With modular I/O controllers, engineers and technicians can expand or adjust system configurations without a complete overhaul. This makes them highly adaptable to growing or changing operational requirements.

Furthermore, modern I/O controllers enhance troubleshooting and maintenance efforts. Many include diagnostic feedback to identify faulty connections, power issues, or malfunctioning devices in real time, allowing technicians to intervene quickly and keep operations running smoothly.

Applications Across Industries

The use of I/O controllers spans a wide range of industries including manufacturing, automotive, food and beverage, mining, water treatment, and building automation. In each of these sectors, real-time control and data collection are critical.

For instance, in a packaging plant, an I/O controller might monitor sensors that detect the position of a product on a conveyor belt and activate an actuator to divert it into the correct packaging lane. In HVAC systems, I/O controllers collect temperature readings and activate dampers or heating elements accordingly.

Even in smart home systems, I/O controllers are being used to manage lighting, security systems, and energy consumption — acting as a scalable bridge between user commands and physical device actions.

Integration with Modern Systems

Modern I/O controllers are designed to integrate seamlessly with industrial PCs, HMIs (Human Machine Interfaces), SCADA systems, and cloud-based platforms. This connectivity ensures that all input and output data can be tracked, analysed, and optimised over time.

Some systems also support hot-swapping and automatic device recognition, allowing for quicker system updates or replacements. With industrial automation moving toward more digitised and decentralised models, the role of a network-capable I/O controller is more important than ever.

Choosing the Right I/O Controller

Selecting the right I/O controller depends on several factors, including the number of inputs and outputs, voltage levels, type of signals (digital or analog), communication protocols, and environmental conditions. For high-risk industries like oil and gas or pharmaceuticals, selecting a safety-certified I/O module is also essential for regulatory compliance and operational safety.

When choosing a controller, you should also consider future scalability, ease of integration, support for remote monitoring, and availability of manufacturer support.

Maintenance and Troubleshooting

Like any piece of equipment, I/O controllers require regular maintenance to ensure ongoing performance. This includes checking for loose wiring, inspecting modules for heat damage or corrosion, and updating firmware where applicable. Most modern I/O controllers come with diagnostic LEDs or remote monitoring tools, making it easier to identify and resolve issues early.

Regular testing of input and output signals, along with calibration of analog channels, is also critical in environments where accuracy and uptime are non-negotiable.

Future Trends in I/O Controller Technology

As industries continue to adopt Industry 4.0 practices, I/O controllers are expected to become even smarter. Enhanced connectivity, support for AI-driven analytics, and integration with cloud platforms will make them not just functional devices, but active participants in predictive maintenance and process optimisation.

Edge computing is another trend gaining traction, where data is processed closer to the source using intelligent I/O controllers. This reduces latency and allows faster decision-making in complex environments.

Conclusion

The I/O controller may not be the most visible part of an industrial system, but it plays a vital role in ensuring everything operates smoothly and efficiently. Whether you’re managing a factory floor, a wastewater plant, or a smart building, a reliable I/O controller serves as the backbone of effective automation. Choosing the right controller — and maintaining it well — can make all the difference in performance, scalability, and long-term success.